Importance of Methane Detection

Methane is a critical resource in global energy production and its demand is expected to increase as global energy consumption grows.

Due to the increasing use of photovoltaic and wind turbine power plants, there also is an increased need for methane-based power plants to cope with intermittence of these energy sources. Despite being an essential resource in global energy production, methane does have its drawbacks. It is highly flammable and emissions could present a serious public safety issue.

Additionally, methane is also a very potent greenhouse gas and is estimated to have 86 times the global warming potential of carbon dioxide over a 20-year time frame. Methane leaks can happen stocastically throughout oil and gas fields, thus very large areas need to be inspected in a timely manner for effective leak prevention. Ground-based surveillance has been traditionally used but has been shown to have limitations due to the geographic scale at which these leaks exist.

Cost-effective detection of methane plumes, particularly from fugitive methane emissions, has thus become a high priority for industry and governments alike.

Any potential solution in detecting these fugitive methane emissions needs to be able to assess a large number of potential emission sources over vast geographical areas, measure the intermittent nature of these fugitive emissions, and be sensitive to the wide range of leak sizes.

The aerial observation and detection developed by Kairos Aerospace using a Xenics camera is thus a promising solution to address these issues.

Spectroscopy: An Efficient Technology For Methane Detection

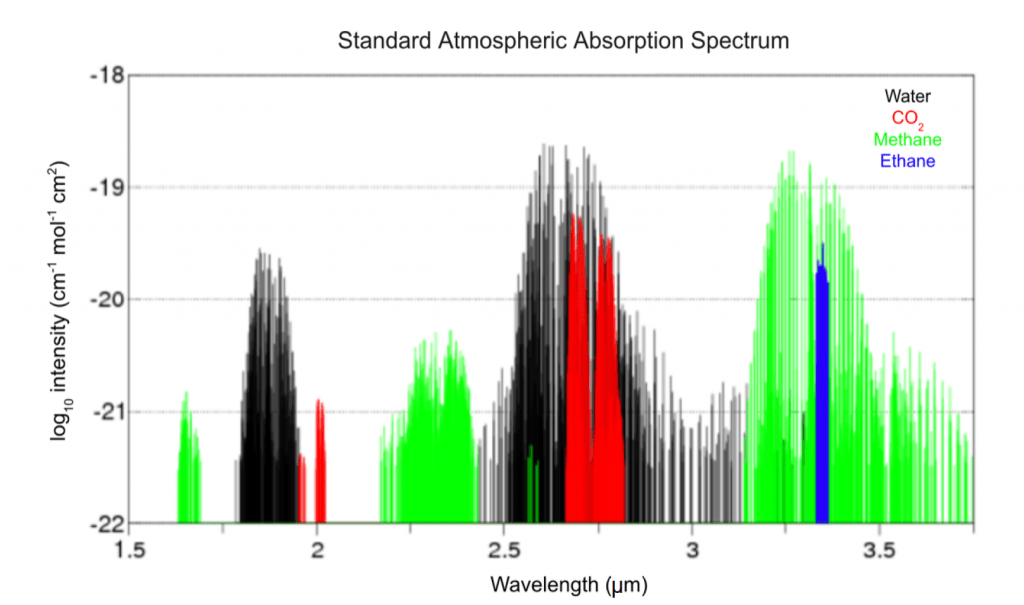

Methane has absorption lines in the infrared (Figure 1), which can be utilized to detect and quantify methane using spectroscopy.

These absorption lines are distinct from other gas species, thus spectroscopic analysis can discriminate methane from other interfering components such as water, carbon dioxide and ethane.

When reflected sunlight passes through a fugitive plume in an oil and gas field, the gas molecules absorb certain wavelengths in the infrared.

The sunlight then reflects off the ground and can be detected through aerial observation. By performing spectroscopic analysis of this reflected sunlight, excess methane from leaking infrastructure can be found.

Figure 1: Absorption spectrum of methane (green), water (black), carbon dioxide (red), and ethane (blue) in the infrared region of the electromagnetic spectrum. Plot courtesy of Spectral-Calc [1].

Kairos solution for methane detection

Kairos Aerospace has developed the LeakSurveyor™, a light aircraft mounted, integrated methane gas imaging system which detects methane emissions from as much as 150 square miles of oil and gas infrastructure in a single day.

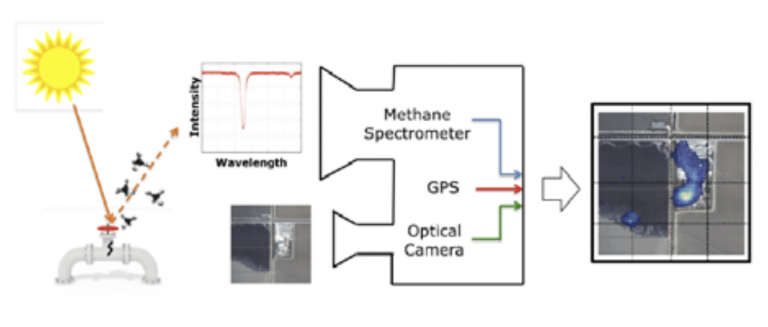

It combines an infrared hyperspectral imaging system with a traditional optical camera and a GPS for accurate and easy-to understand mapping of methane emissions (Figure 2). Raw spectral data is processed using proprietary, innovative data analytics including atmospheric retrieval techniques and advanced chemometric routines in a fully ephemeral cloud processing architecture.

Then geolocated methane images are superimposed on optical images that were collected with the methane data. This combination of optical data, precise geolocation that integrates with customers’ in-house mapping tools, and methane detection allows the customer to determine the location and likely source of the methane plume.

Figure 2: concept of the LeakSurveyor™.

Choosing the Right Infrared Camera

In order to get an efficient system, the choice of the infrared camera is an important step. High-precision spectroscopy requires a camera that has excellent gain management, high linearity and very few defective pixels.

To accommodate the geographic scale required to monitor oil and gas fields, this camera’s manufacturing needs to be very reproducible in order to simplify integration and to allow interchangeability.

Finally, a rugged, lightweight, low power consumption design is essential for the camera to be able to operate on the wing of a small aircraft. Kairos Aerospace chose Xenics as their camera supplier because Xenics cameras fulfil these key characteristics.

Achievements

Kairos has been operating the LeakSurveyor™ for more than 6 years. During this time more than 260.000 square kilometers have been inspected in 17 regions in North and South America and Europe. Since 2019, Kairos has helped clients eliminate more than 43,6 Billon Cubic Feet of methane from being released in the atmosphere thanks to the LeakSurveyor™.

In the fight against global warming, this corresponds to an equivalent of 73.3 MT of CO2 prevented from being released into the atmosphere (20-year CO2e [2]) which is the equivalent of removing 15,8 million cars from the road for a year.

Finally, in the last 3 years these preventative actions have saved customers an estimated $128M US.